It will provide an overview of the application of Deepal S07 motor technology, which is coming soon to Pakistan.

This article provides more information on the design and operation of PMSM. And interestingly enough, the laws of physics work with different types of motor construction.

Introduction

A permanent magnet synchronous motor (PMSM) combines the features of an induction motor and a brushless DC motor, offering higher power density than an induction motor. It consists of a permanent magnet rotor and windings on the stator, similar to a brushless DC motor. However, the stator construction with windings is designed to produce a sinusoidal flux density in the air gap, resembling that of an induction motor. Due to its advantages, permanent synchronous motors are widely used in electrical drives. PMSM offers superior performance due to its characteristics such as high power density, high efficiency, lower mass, and lower moment of inertia.

This sounds like a great initiative! Creating a community forum for vehicle enthusiasts in Pakistan to discuss NEV technology can be a great tool. With thousands of like-minded people coming together to share their knowledge and insights, this platform can provide a wealth of information on the latest developments in electrical technology as well as discussions on various topics related to NEVs. It also provides a place to chat. I am sure it will be exciting to be a part of this community and learn from others who are passionate about sustainable and innovative technology.

PMSMs are brushless AC synchronous motors that are highly reliable and efficient. They have a permanent magnet rotor, which allows for higher torque, a smaller frame size, and no rotor current

Here are some more features of a permanent magnet synchronous motor (PMSM):

Simple construction: Easy to maintain

Rugged: Can operate reliably at high speeds

Efficient: Almost no rotor losses

High torque-to-weight ratio

Smooth torque

Low noise

Cost-effective

High power density

High torque/inertia ratio

Less maintenance

What is the power rating of PMSM?

Power range 0,25 to 75 kW – 4-, 6-, 8- and 12-pole design – 500 to 3.000 r.p.m. – Torque 0,55 Nm to 700 Nm – Sizes 56 to 280 – Degree of protection IP55 – Thermal class 155 [F/B] The application range and usage of this new design series is comparable to asynchronous motors for pumps, ventilators, compressors and. (Research and development in this category is ongoing.)

Is a permanent magnet synchronous motor AC or DC?

A permanent magnet synchronous motor (PMSM) is an AC synchronous motor. The permanent magnets in the PMSM’s excitation system provide field excitation. The PMSM’s rotation speed is synchronized with the AC’s electric frequency, and it rotates at a constant speed regardless of the load.

Working principle:

A PMSM motor works on the same principle as a synchronous motor. PMSM motors start out as squirrel-cage induction motors. When a three-phase power source energizes the three-phase winding of the stator, a rotating magnetic field is created in the air gap. At synchronous speed, the rotor field magnetically locks with the stator poles, producing torque and allowing the rotor to rotate.

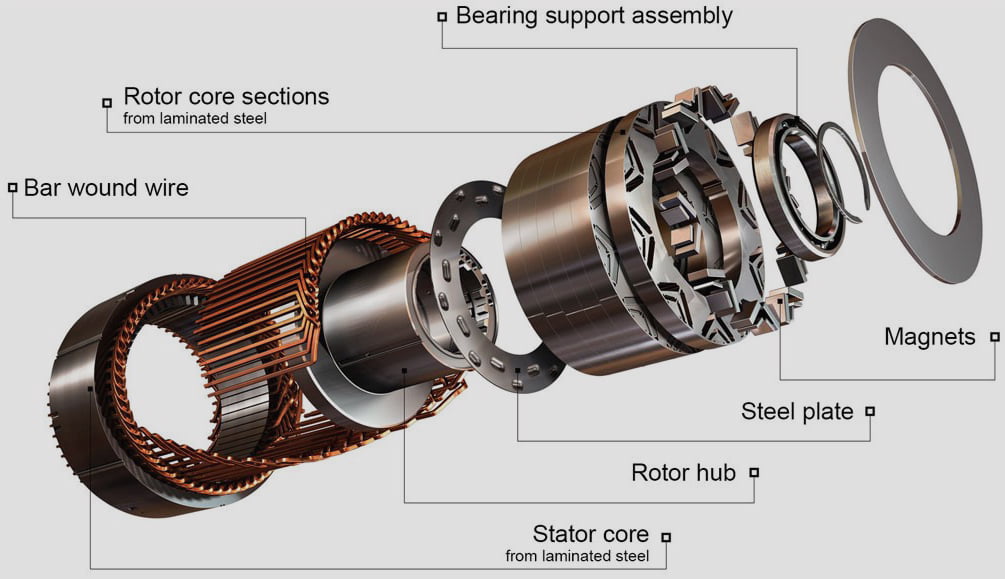

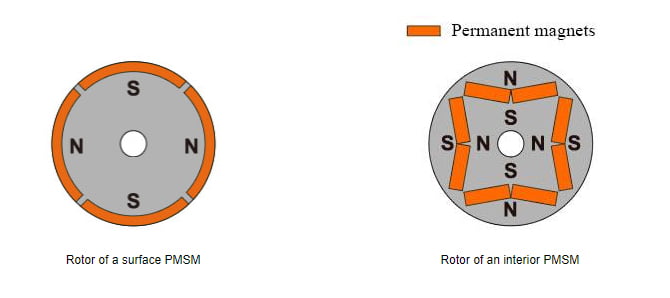

Construction and types of motor

A permanent magnet synchronous motor, like any rotating electric motor, consists of a rotor and a stator. The stator is a fixed part. The assembly comprises a rotor and a stator. Permanent magnets are mounted on the rotor and there is no field winding in the rotor.

Permanent magnetic fields are used to create poles. Because of their high permeability, permanent magnets used in motors are made of samarium cobalt and medium, iron and boron. The most commonly used permanent magnet is neodymium-boron-iron because of its cost-effectiveness and ease of availability.

Last Thing:

With recent advances in processors and intelligent computing, the permanent magnet synchronous motor (PMSM) has a place in high-performance drives. Advantages of permanent magnet synchronous motors are their simple structure, compact size, excellent efficiency, and high power output. The advantages of PM machines have recently made them very attractive for ‘direct drive’ applications such as hybrid electric vehicles (HEV) and electric cars (EV)

PMSM motors have become increasingly prominent in EVs these days. They provide everything from higher power to improved safety and performance to an electric vehicle.